- +1-707-722-7066

- care@flashtestbio.com

English

FLASHTEST is more than just a manufacturer; we're a partner in your diagnostic success. We recognize that each market has unique requirements, which is why we offer comprehensive customization services. From original design and development (ODM) and efficient manufacturing (OEM) to full technology transfer and production setup, we provide the expertise and support you need. Our core strengths lie in molecular diagnostics, immunology, and lab automation, with a strong focus on PCR and immunofluorescence technologies. We're committed to building long-term partnerships with our international clients. Contact us to explore how we can work together.

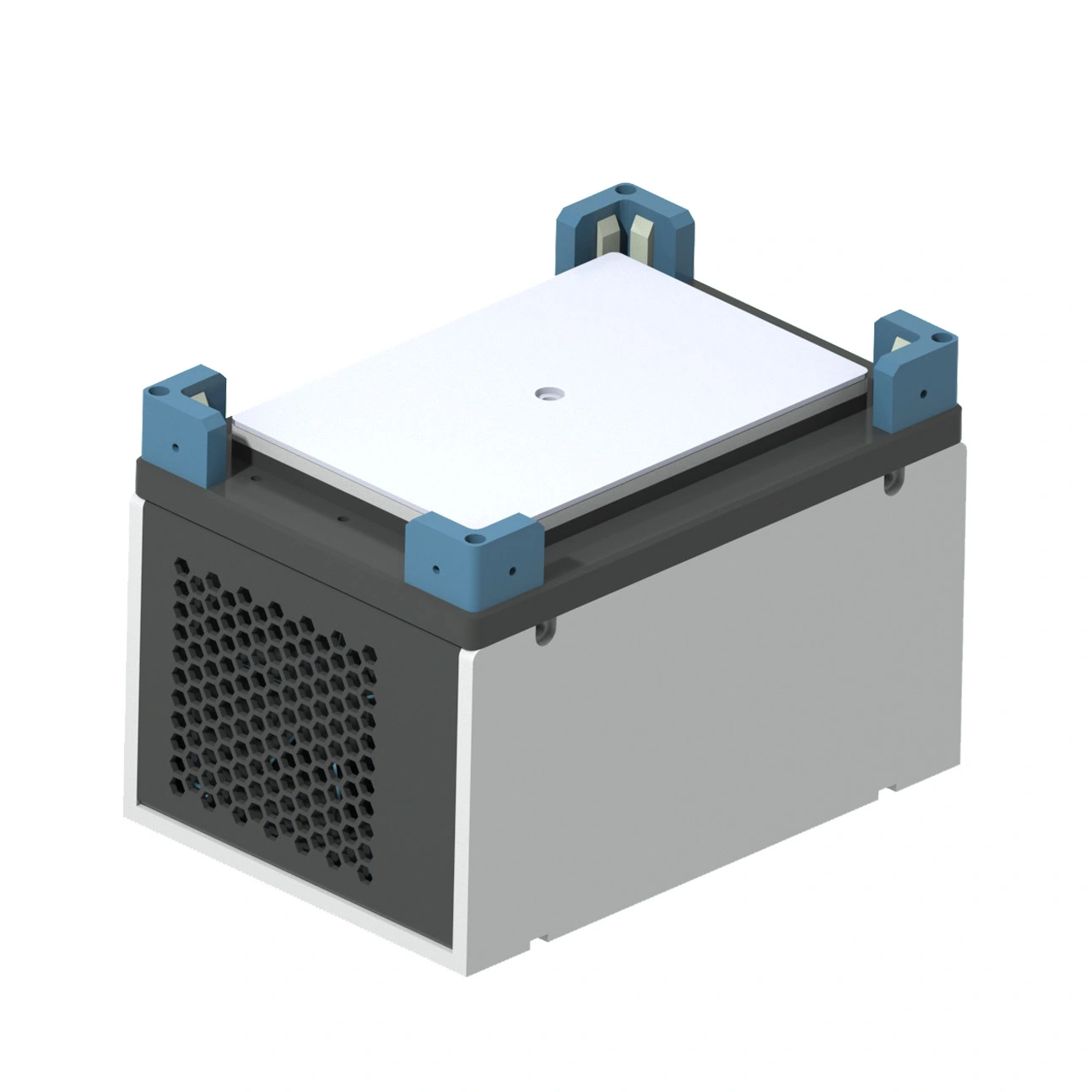

Wide Temperature Range (4°C to 110°C): Versatile temperature control to accommodate diverse experimental needs.

Precise Temperature Control: Fast heating and cooling cycles, ensuring accurate and efficient experimental results.

Excellent Temperature Uniformity: Ensures consistent temperature across wells for reliable and reproducible outcomes.

Multiple Temperature Control Modes: Includes options like constant temperature, programmed heating/cooling, and gradient PCR for varied applications.

Programmable Temperature Curves: Customizable profiles to meet specific experimental requirements.

Multiple Well Configurations: Options for 8-well or 96-well plates, providing flexibility for different throughput needs.

Compact Design: Space-saving layout, ideal for optimizing laboratory space without compromising functionality.

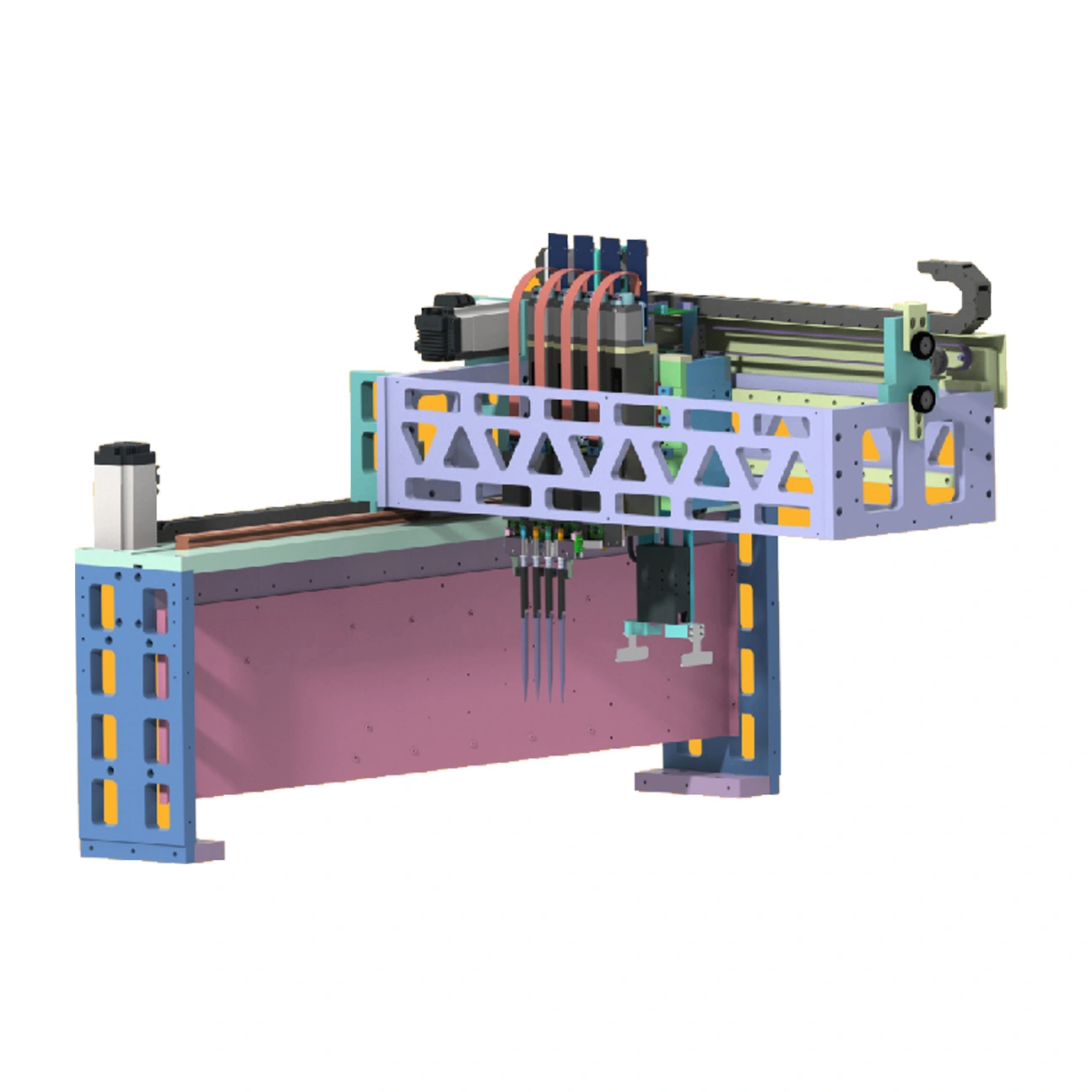

Temperature Control Range (0°C to +105°C): Offers a wide temperature range to support diverse experimental requirements.

Multiple Temperature Control Modes: Includes options such as constant temperature, programmed heating/cooling, and gradient control for flexible experimentation.

Programmable Temperature Curves: Customizable temperature profiles to meet the needs of complex experimental protocols.

Versatile Adapters: Supports different reagent needs with adapters for test tubes, microplates, centrifuge tubes, and more.

Standard Communication Interfaces: DB9 interface and CAN communication provide reliable, industry-standard connectivity.

Standalone or Workstation Integration: Can be used independently or seamlessly integrated with a workstation for enhanced workflow.

Independent Heating and Cooling Modules: Separate control for heating and cooling modules, optimizing efficiency and flexibility.

Multi-Channel Liquid Handling Module: Built on the standard ADP pneumatic pump, enabling multi-channel liquid handling for versatile applications.

Independent 4-Channel Control: Precise movement and accurate liquid aspiration and dispensing for each of the 4 channels.

Liquid Level Detection and Alarm Systems: Includes liquid level detection, blockage alarms for aspiration/dispensing, and air aspiration alerts to ensure reliable operation.

RS-485 Connectivity: Allows for the connection of up to 4 channels in series, with adjustable spacing and independent Z-axis control for enhanced flexibility.

Pneumatic Liquid Level Detection: Capable of detecting blockages and preventing air aspiration to ensure continuous accuracy.

Compatible with TECAN White Non-Conductive Tips: Supports high-quality, non-conductive tips for better performance.

Multiple Communication Protocols: Supports various protocols such as RS-232, CAN, and more, enabling seamless integration with other devices.

High Pipetting Precision: Achieves CV < 2% at 50 µL, ensuring accurate and reliable liquid handling.

Compact Design: Features a space-efficient structure with comprehensive monitoring of TIP head status and air aspiration detection during the entire pipetting process.

Pressure-Based Liquid Level Detection: Ensures accurate liquid level detection using a pressure sensor for precise control.

Simplified Command Set: Comes with an intuitive command set and a user-friendly upper-level software interface for easy control and operation.

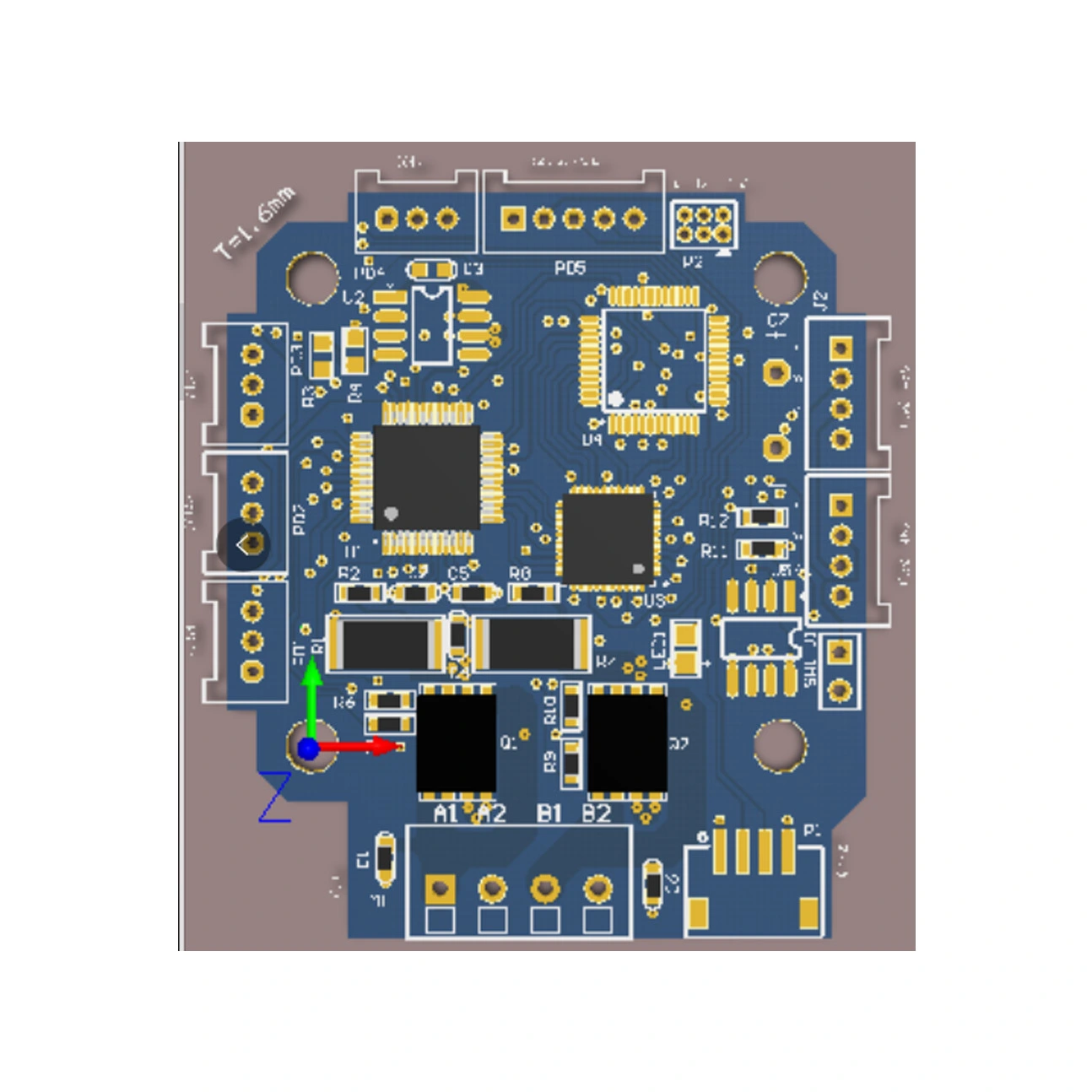

RS-485/CAN Bus Communication Control: Supports communication via RS-485 and CAN protocols, ensuring compatibility with a range of laboratory devices.

TECAN-Compatible Non-Conductive TIPs: Supports TECAN’s white non-conductive tips for optimized performance and accuracy.

Multiple Pipetting Modes: Includes forward pipetting, reverse pipetting, multiple dispensing, continuous dispensing, and more, catering to a variety of experimental needs.

Low Residue Pipetting: Minimizes liquid residue inside the TIPs, enhancing pipetting accuracy and reducing potential cross-contamination.

Simultaneous Grasping and Continuous Rotation: Capable of performing both gripping and continuous rotation actions simultaneously for enhanced flexibility.

Dual Servo Systems: Features two independent servo systems for a compact design and efficient operation.

High Clamping Force and Torque: Delivers strong gripping power and high torque, ensuring reliable handling of various objects.

Precise Force and Position Control: Enables precise control over both gripping force and rotational position, ensuring accuracy and reliability.

Independent Gripping and Rotation Control: Offers separate control for gripping and rotation, allowing for simultaneous operation without interference.

High-Speed Rotation and Quick Gripping: Facilitates rapid rotation and gripping actions to improve workflow efficiency and throughput.

Programmable Gripping Force and Rotation Speed: Allows for customization of gripping force and rotational speed, catering to different handling requirements.

Compact Design with Versatile Mounting Options: Features a compact structure supporting at least five flexible mounting configurations, accommodating various gripping tasks.

Fast Gripping and Release: The jaw opening and closing time can be as fast as 0.2 s/0.2 s, meeting the high-speed and stable gripping demands of production lines.

Adjustable Gripping Force: Special transmission design and drive algorithms compensate for force variations, allowing continuous adjustment of the gripping force, with a repeatability precision of 0.1 N.

High Rigidity Structure: The rigid design ensures the stability of both gripping and rotation, minimizing vibrations and deformation during operation.

Corrosion-Resistant and Biocompatible Materials: Constructed with materials that are resistant to corrosion and are biocompatible, making it suitable for lab environments and preventing sample contamination.

Built-in Sensors for Closed-Loop Control: Equipped with force sensors, position sensors, and encoders, enabling closed-loop control and providing precise feedback for optimized performance.

Integrated Motor Design with Modular Functionality: The system features an integrated motor design, with the flexibility to operate in a standalone mode if necessary.

RS485 and CAN Communication Support: Supports both RS485 and CAN communication protocols, ensuring compatibility with various automation systems.

Torque or Position Control Mode: The drive and control unit can operate in torque or positioning mode, controlled via communication commands, eliminating the need for pulse signals.

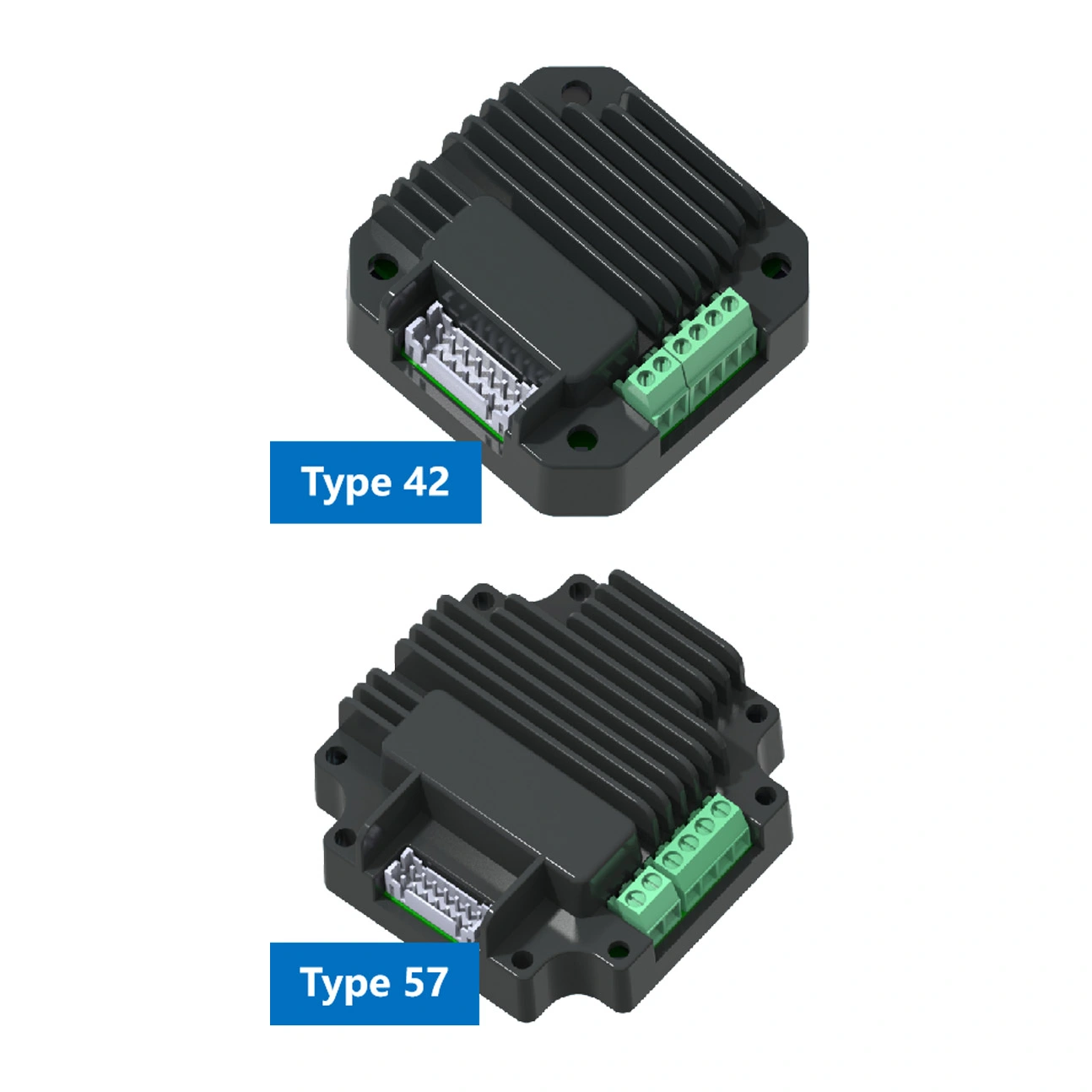

Precision-Cast Aluminum Alloy Housing: Built with a high-strength, low-thermal-rise, and corrosion-resistant precision-cast aluminum alloy housing, ensuring durability and reliability in demanding environments.

Supports Multiple Motor Types: Compatible with various motor types, including DC motors, stepper motors, and servo motors, providing flexibility in system integration.

Multiple Control Modes: Offers various control options, including speed control, position control, torque control, and current control, to meet different operational requirements.

TMC Silent, Low-Cost Control Solution: The system employs TMC’s quiet and cost-effective control solution, ensuring reliable operation with minimal noise and high motion efficiency.

Support for Low-Cost Motors: Designed to enhance the performance of low-cost motors, enabling them to achieve movement quality comparable to higher-end motors.

RS485 Protocol for Networking: The system supports RS485 communication protocol, enabling easy networking and integration into larger systems.

Position and Torque Modes: Capable of operating in both position and torque control modes, providing flexibility for various applications.

Closed-Loop Control: Features precise closed-loop control for position, speed, and torque, improving dynamic performance and system resistance to interference.

Communication with Host Software or PLC: Allows for seamless communication with host software or PLCs for remote control, monitoring, parameter configuration, data collection, and fault diagnosis.

Get In Touch With Us Now!

Tel:

+1-707-722-7066Email:

care@flashtestbio.comAdd:

Blk A4 - F2, Liyuan Development Zone, Binhu District, Wuxi, China